The combined cycle power plant is power plant which consists of two power cycles.

1.Brayton Cycle

2.Rankine Cycle

Brayton Cycle:

In Brayton cycle Gas turbine is powered by gas to spin the generator and produce electrical power. In this cycle Gas turbine also can be power by furnace oil or High speed diesel. The efficiency of brayton cycles gas turbines is up to 40%.

The other cycle is called HRSG (Heat recovery steam generation). In this process, steam is generated from the exhaust of gas turbine and this is fed to steam turbine to spin the attached generator. The temperature of exhaust is too high near 650c which is enough to generate useable steam. overall efficiency of power plant is increased from 40% to 54%. There are many other accessories for combined cycle power plant which work with parallel as like auxiliary pumps for fuel, water , lube oil, air intake etc.

rankine cycle for detailed procedure.

rankine cycle is cycle of steam power plant which is explained cycle by cycle.

A steam turbine power plant converts the energy of the fuel into the shaft work continuously and ultimately from the shaft work, electricity is produced. In the boiler, there is combustion of fuel (fossil fuel) like oil, natural gas, and coal or fissile fuel such as Uranium or Thorium to produce steam.

In the combustion process, heat generated is supplied to the boiler which is a heat exchanger. Boiler is a tube separating two fluids by a walls and thermal conductivity of this wall is very high. In the Nuclear Power plant, the furnace is replaced by Nuclear reactor.

The steam is produced at very high temperature and pressure which expands in steam turbine to produce Mechanical energy and the electrical energy.

Where

Mf = Mass of fuel

C.V = Calorific value

Wp = Work of the Pump

Q1 = Heat Supplied

Q2 = Heat rejected

Wt is the shaft work, which is form of mechanical energy. Steam coming from the turbine is fed to the condenser where condensation of the steam takes place. Here heat is extracted from steam to convert it into liquid. Steam emitted from the turbine has both liquid and vapor phases.

River or see water can be used to extract heat from steam and there is change of phase from vapor to liquid. If no river or see is present in nearby area, cooling tower is needed to supply cold water to condenser. The pressure inside the condenser is 10% of the atmospheric pressure. So, a pump is used to raise the pressure from condenser pressure to boiler pressure. Therefore steam turbine power plant work in a sequence.

B —–> T ——-> C ——> P ——> B

And the cycle is going on repeatedly.

Co-Generation:

The production of electric power and heat in a single unit is called co-generation. Co-generation is applicable to the industries like paper, Textile, sugar, chemical, cement etc.

Advantages of Cogeneration:

Isothermal process is maintained by steam as it is the best fluid to maintain constant temperature. The constant process is maintained by using its latent heat of vaporization.

Process is good for safety point of view. For example in inflammable environment, e.g in oil refinery, the direct heat can blow up the whole plant. Steam use for this process is safe.

Feasibility of the plant must be seen before choosing a cogeneration plant.

There are two types of cogeneration cycle.

A. Topping cycle:

B. Bottoming cycle:

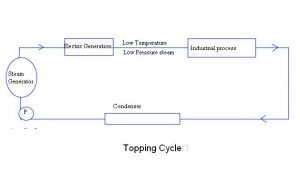

Topping cycle:

It is cycle where main emphasis is on the production of electricity. High grade steam is used to generate power and then low grade steam is used in industrial process. Topping cycle finds its application in process industry.

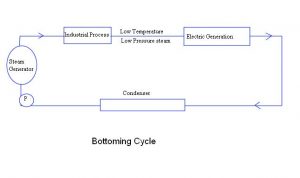

Bottoming Cycle:

Here the steam generated by the steam generator is mainly utilized in the Industrial process and then the steam from the discharge of industrial process is used to generate electricity.

In the cement industry, this type of cycle is applicable as the steam required there should be high grade. ( High temperature and pressure)