Actuator is crucial components in many automation systems. They help convert energy into movement, enabling machines and devices to function smoothly. From robotics to heavy machinery, actuators play a vital role in today’s technology.

What are actuators :

An actuating levers are devices that creates motion. It takes energy, whether electrical, hydraulic, or pneumatic, and converts it into mechanical movement. This process is essential in various technologies, allowing for precise control over operations.Aapplications across various industries

Actuators are found in many sectors, including:

- Manufacturing: Automating assembly lines.

- Automobiles: Adjusting seats and windows.

- Aerospace: Controlling flight surfaces.

- Robotics: Enabling movement in robotic arms.

The rising demand for electrical actuators in modern technology

With advancements in automation and smart technology, the demand for actuating solenoid is increasing. Industries look for better efficiency, precision, and speed, driving innovation in actuating levers design.

A Comprehensive Overview

Electric Actuating devices: Motors, Linear Actuating, and Solenoids

Electric actuating knobs use electrical energy to produce motion. They include:

- Motors: Commonly used in household appliances.

- Linear actuators: Move in a straight line.

- Solenoids: Create linear movement through electromagnetic forces.

Pros and cons of electric actuating solenoids:

Pros:

- High precision

- Easy to control

Cons:

- Limited power for heavy loads

- Dependency on electrical supply

Specific applications of electric actuating solenoids (e.g., robotics)

Electric solenoids are ideal for robotics. They provide accurate movements, essential for tasks like assembling components or performing delicate operations.

Hydraulic Actuating cyclinders:

Hydraulic cylinders use fluid pressure to generate motion. They’re powerful and can lift heavy loads.

Advantages and limitations of hydraulic cyclinders

Advantages:

- High force output

- Excellent for heavy machinery

Limitations:

- Risk of leaks

- Requires a hydraulic fluid system

Case study: Hydraulic lever in heavy machinery

In construction, hydraulic lever are used in excavators and bulldozers. They provide the necessary power to lift and move large materials efficiently.

Pneumatic Actuating knobs: Utilizing Compressed Air for Motion

Pneumatic actuating knobs operate using compressed air. They are lightweight and fast, making them suitable for many applications.

Comparison of pneumatic actuating knobs with other types

While hydraulic levers handle heavier loads, pneumatic actuating knobs are preferred for speed and lighter applications, like packaging and assembly lines.

Applications of pneumatic cylinders in manufacturing

In manufacturing, pneumatic cylinders are used for conveyor systems and material handling processes. They enhance speed while maintaining precision.

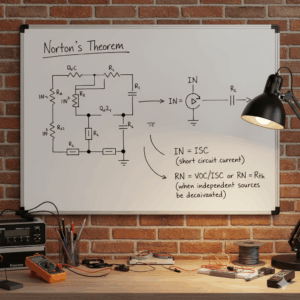

How Actuating lever Work: Principles and Mechanisms

Understanding the Conversion of Energy into Motion

Actuating levers convert various forms of energy into motion. For electric actuating solenoids, electric energy leads to rotational or linear movement. Hydraulic actuating levers depend on fluid pressure, while pneumatic actuators utilize air pressure.

Detailed explanation of the underlying physics

The core principle involves Newton’s laws of motion. By applying force, electrical levers generate movement, which can be controlled and manipulated based on system needs.

Diagrams illustrating different actuation mechanisms

Visual aids can clarify how each type operates:

- Electric solenoids show motor actions.

- Hydraulic levers depict fluid flow.

- Pneumatic systems illustrate air movement.

Control Systems and Feedback Mechanisms

Precision is vital in motion converter systems. Control systems ensure accurate operation, allowing for feedback to adjust movements based on real-time conditions.

Importance of precision control in actuating systems

Accurate control helps prevent errors. In robotics, for instance, precise actuating movements ensure tasks are completed as intended.

Examples of various control methods used

- Open-loop control: Simple systems without feedback.

- Closed-loop control: Uses sensors to adjust movements.

Selecting the Right Actuating tools for Your Application

Key Factors to Consider When Choosing an Actuating knobs

Consider the following factors:

- Environmental factors: Temperature and humidity can affect performance.

- Force, speed, and stroke requirements: Each application has specific needs.

- Budget and maintenance considerations: Look for durability and low maintenance.

Matching Actuators Specifications to Project Needs

Finding the right actuators involves matching specifications to needs. Analyze system requirements, including load capacity and speed.

Steps for effective actuators selection

- Define your application goals.

- Determine the necessary specifications.

- Research available options.

- Consult with manufacturers for insights.

Resources for finding suitable actuators

Online databases, manufacturer websites, and engineering forums offer valuable information about various actuators types.

Actuators Maintenance and Troubleshooting

Regular Maintenance Procedures to Extend Lifespan

Proper maintenance can prolong actuators lifespan. Regular checks can identify potential issues.

Cleaning, lubrication, and inspection guidelines

- Clean the actuators regularly to remove dust and debris.

- Lubricate moving parts to reduce friction.

- Inspect for wear and tear to prevent failures.

Common Actuating levers Problems and Their Solutions

Some common issues include:

- Overheating: Check for blockages.

- Inconsistent movement: Inspect electrical connections.

- Leaking fluids: Replace seals or gaskets.

The Future of Actuating Technology

Emerging Trends and Innovations in Actuator Design

New designs and materials are enhancing actuating lever performance. Smart technologies are enabling more intelligent control.

Advancements in materials science and manufacturing

Innovations in materials like composites lead to lighter, stronger actuators. This shift boosts efficiency and performance in many applications.