The facility inspection for energy Audit

The Facility Inspection:

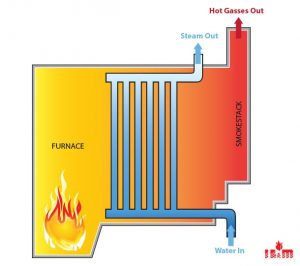

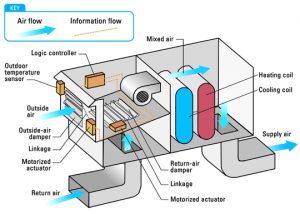

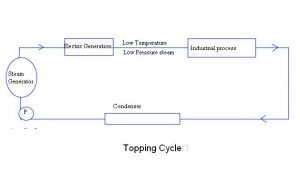

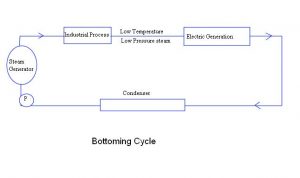

Once all of the basic data has been collected and analyzed, the audit team should tour the entire facility to examine the operational patterns and equipment usage, and should collect detailed data on the facility itself as well as on all energy using equipment. This facility inspection should systematically examine the nine major systems within a facility, using portable instrumentation and common sense guided by an anticipation of what can go wrong. These systems are: the building envelope; the boiler and steam distribution system; the heating, ventilating, and air conditioning system; the electrical supply system; the lighting system, including all lights, windows, and adjacent surfaces; the hot water distribution system; the compressed air distribution system; the motors; and the manufacturing system. Together, these systems account for all the energy used in any facility; examining all of them is a necessary step toward understanding and managing energy utilization within the facility.

- 1. Introductory Meeting

The audit leader should start the audit by meeting with the facility manager and the maintenance supervisor. He should briefly explain the purpose of the audit and indicate the kind of information the team needs to obtain during the facility tour. If possible, a facility employee who is in a position to authorize expenditures or make operating policy decisions should be at this initial meeting.

- Audit Interviews

The auditor must also interview the floor supervisors and equipment operators to understand the building and process problems. Line or area supervisors usually have the best information on the times their equipment is used. The maintenance supervisor is often the primary person to talk to about types of lighting and lamps, sizes of motors, sizes of air conditioners and space heaters, and electrical loads of specialized process equipment. Finally, the maintenance staff must be interviewed to find the equipment and performance problems.

- Initial Walk through Tour

An initial facility/plant tour should be conducted by the facility/ plant manager, and should allow the auditor or audit team to see the major operational and equipment features of the facility. The main purpose of the initial tour is to obtain general information, and to obtain a general understanding of the facility’s operation. More specific information should be obtained from the maintenance and operational people during a second and more detailed data collection tour.

- Identification of EMO’S

As the audit is being conducted, the auditor should take notes on potential EMOs that are evident. As a general rule, the greatest effort should be devoted to analyzing and implementing the EMOs which show the greatest savings, and the least effort to those with the smallest savings potential. Therefore, the largest energy and cost activities should be examined carefully to see where savings could be achieved. Identifying EMOs requires a good knowledge of the available energy efficiency technologies that can accomplish the same job with less energy and less cost. For example, over-lighting indicates a potential lamp removal or lamp change EMO, and inefficient lamps indicate a potential lamp technology change. Motors with high use times are potential EMOs for high efficiency replacements. Notes on waste heat sources should indicate what other heating sources they might replace, and how far away they are from the end use point. Identifying any potential EMOs during the walk-through will make it easier later on to analyze the data and to determine the final EMO recommendations.

- Energy Audit Report

The next step in the energy audit process is to prepare a report which details the final results of the energy analyses and provides energy cost saving recommendations. The length and detail of this report will vary depending on the type of facility audited. A residential audit may result in a computer printout from the utility. An industrial audit is more likely to have a detailed explanation of the EMOs and benefit-cost analyses. The following discussion covers the more detailed audit reports. The report should begin with an executive summary that provides the owners/managers of the audited facility with a brief synopsis of the total savings available and the highlights of each EMO. The report should then describe the facility that has been audited, and provide information on the operation of the facility that relates to its energy costs. The energy bills should be presented, with tables and plots showing the costs and consumption. Following the energy cost analysis, the recommended EMOs should be presented, along with the calculations for the costs and benefits, and the cost-effectiveness criterion. Regardless of the audience for the audit report, it should be written in easy format.

Energy Audit Report Format:

- Executive Summary

A brief summary of the recommendations and cost savings

- Table of Contents

- Introduction

Purpose of the energy audit

Need for a continuing energy cost control program

- Facility Description

Product or service, and materials flow

Size, construction, facility layout, and hours of operation

Equipment list, with specifications

- Energy Bill Analysis

Utility rate structures

Tables and graphs of energy consumptions and costs

Discussion of energy costs and energy bills

- Energy Management Opportunities

Listing of potential EMOs

Cost and savings analysis

Economic evaluation

- Energy Action Plan

Recommended EMOs and an implementation schedule

Designation of an energy monitor and ongoing program

- Conclusion

Additional comments not otherwise

- The Energy Action Plan

An important part of the energy audit report is the recommended action plan for the facility. Some companies will have an energy audit conducted by their electric utility or by an independent consulting firm, and will then make changes to reduce their energy bills. They may not spend any further effort in the energy cost control area until several years in the future when another energy audit is conducted. In contrast to this is the company which establishes a permanent energy cost control program, and assigns one person—or a team of people—to continually monitor and improve the energy efficiency and energy productivity of the company. Similar to a Total Quality Management program where a company seeks to continually improve the quality of its products, services and operation, an energy cost control program seeks continual improvement in the amount of product produced for a given expenditure for energy. The energy action plan lists the EMOs which should be implemented first, and suggests an overall implementation schedule. Often, one or more of the recommended EMOs provides an immediate or very short payback period, so savings from that EMO—or those EMOs—can be used to generate capital to pay for implementing the other EMOs. In addition, the action plan also suggests that a company designate one person as the energy monitor or energy manager for the facility if it has not already done so. This person can look at the monthly energy bills and see whether any unusual costs are occurring, and can verify that the energy savings from EMOs is really being seen. Finally, this person can continue to look for other ways the company can save on energy costs, and can be seen as evidence that the company is interested in a future program of energy cost control.

Implementation:

After the energy consumption data has been collected and analyzed, the energy-related systems have been carefully examined, the ideas for improvement have been collected, and management commitment has been obtained, the next steps are to obtain company support for the program, to choose goals, and to initiate action.

- Energy Action Team

Now that the preliminary audits have uncovered some energy management measures that can save significant amounts of money or can substantially improve production, funding for the changes and employee support are two additional critical ingredients for success. These can best be obtained with the help of a committee, preferably called something like the energy action team.

No program will work within a company without employee support, particularly such a program as energy management which seems to promise employee discomfort at no visible increase in production. Therefore, one function of the energy action committee is to give representation to every important political group within the company. For this purpose, the committee must include people from unions, management, and every major group that could hinder the implementation of an energy management plan. The committee must also include at least one person with financial knowledge of the company, a person in charge of the daily operation of the facility, and line personnel in each area of the facility that will be affected by energy management.

- Goals

At least three different kinds of goals can be identified. First, performance goals, such as a reduction of 10 percent in Btu/unit product, can be chosen. Such goals should be modest at first so that they can be accomplished— in general, 10-30 percent reduction in energy usage for companies with little energy management experience and 8-15 percent for companies with more. These goals can be accompanied by goals for the reduction of projected energy costs by a similar amount. The more experienced the company is in energy management, the fewer easy saving possibilities exist; thus lower goals are more realistic in that case.

A second type of goal that can be established is an accounting goal. The ultimate objective in an energy accounting system is to be able to allocate the cost of energy to a product in the same way that other direct costs are allocated, and this objective guides the establishment of preliminary energy accounting goals. A preliminary goal would therefore be to determine the amount of electricity and the contribution to the electrical peak from each of the major departments within the company. This will probably require some additional metering, but the authors have found that such metering pays for itself in energy saving (induced by a better knowledge of the energy consumption patterns) in six months or less.

The third type of goal is that of employee participation. Even if an energy management program has the backing of the management, it will still fail without the support and participation of the employees. Ways to measure this include the number of suggestions per month; the dollar value of improvements adopted as a result of employee suggestions, per month; and the number of lights left on or machines left running unnecessarily, on a spot inspection. Work sampling has been used to estimate the percentage of time that people are working at various tasks—it can be used equally well on machines.

- Implementing Recommendations

In addition to providing and evaluating ideas, setting goals, and establishing employee support, the energy action committee has the duty of implementing the most promising ideas that have emerged from the energy evaluation process. Members of the committee have the responsibility to see that people are assigned to each project, that timetables are established, that money is assigned, and that progress reporting procedures are set up and followed.

- Monitoring

Energy management is not complete without monitoring and its associated feedback, and neither is the energy audit process. In an energy audit, monitoring discloses what measures contributed toward the company goals, what measures were counterproductive, and whether the goals themselves were too low or too high. Monitoring consists of collecting and interpreting data. The data to collect are defined by the objectives chosen by the energy action committee. At the very least, the electrical and gas bills and those of other relevant energy sources must be examined and their data graphed each month. Monthly graphs should include: the total energy used of each type (kWh of electricity, therms [105 Btu] of gas, etc.); the peaks, if they determine part of the cost of electricity or gas; and any other factors that contribute to the bills. At the same time, other output-related measures, such as Btu/ ton, should also be calculated, recorded, and graphed. The monitoring data should provide direct feedback to those most able to implement the changes. Often this requires that recording instruments be installed in a number of departments in addition to the meters required by the utility company. The additional expense is justified by increased employee awareness of the timing and amounts of energy consumed, and usually this awareness leads to a reduction in energy costs.

Metering at each department also enables management to determine where the energy is consumed and, possibly, what is causing the energy consumption. Such metering also helps each department manager to understand and control the consumption of his or her own department. Monitoring should result in more action. Find what is good, and copy it elsewhere. Find what is bad, and avoid it elsewhere. If the goals are too high, lower them. If the goals are too low, raise them. Wherever the difference between the planned objectives and the achievements is great, initiate an analysis to determine the reasons and then develop new objectives, initiate new action, and monitor the new results. In this way, the analysis, action, and monitoring process repeat itself.