What Is a Core Balance Current Transformer?

Definition and Basic Functionality

A core balance current transformer is a special device designed to detect tiny differences in electrical currents. Unlike typical current transformers, CBCTs focus on the balance between multiple currents. When everything is working right, the currents flowing in different parts cancel each other out. But if a leak or fault occurs, that balance shifts. CBCTs sense this imbalance and alert us to trouble.

Components of a Core Balance Current Transformer

CBCTs are made of a core — often metal — wound with multiple coils of wire. The core’s material influences sensitivity and accuracy. The wires are designed to detect small changes in magnetic flux caused by current imbalance. They’re housed with insulation and built to withstand environmental factors, especially in industrial settings.

Types of Core Balance Current Transformers

You’ll find two main types. Split-core CBCTs open up for easy installation around existing wiring, making them popular for retrofits. Solid-core versions are permanently fixed but often more precise. Some models are made specifically for low-voltage settings, while others handle high currents. Picking the right type depends on your application needs.

Core Balance Current Transformers Working

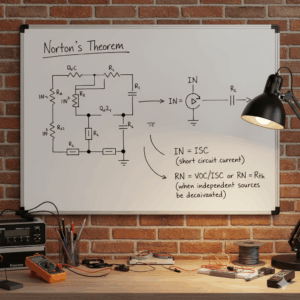

Operational Principles

CBCTs operate on a simple idea: when currents travel symmetrically, they produce magnetic fields that cancel out. If there’s an imbalance, a magnetic field appears. This imbalance usually hints at a leakage current or fault. The CBCT detects this and triggers alarms or protective devices.

Measurement and Signal Output

These transformers generate a small current or voltage proportional to the imbalance. This signal can then be fed into relays or monitoring systems. By focusing on the differential current — the difference between two or more currents — CBCTs provide clear indication of issues without false alarms.

Typical Applications

Core balance current transformers are used in many areas: detecting ground faults in residential wiring, monitoring residual current to prevent electric shocks, and measuring leakage currents in sensitive equipment. They are vital for systems requiring quick fault detection and safety checks.

Advantages

Enhanced Safety and System Protection

CBCTs can identify faults almost immediately, stopping damage before it worsens. They keep people safe by detecting dangerous leaks early. This quick response can prevent fires, electrocution, or costly equipment downtime.

Improved Accuracy and Reliability

High precision in catching tiny current imbalances means fewer false alarms. When calibrated right, CBCTs offer reliable data, ensuring your system reacts only when genuinely needed. This accuracy improves overall system health and reduces maintenance.

Ease of Installation and Maintenance

Split-core models can be snapped around existing wires, making upgrades simple. They require minimal system interruption. Regular checks and calibration ensure continued accuracy, but the design keeps maintenance straightforward.

Limitations

Sensitivity to External Magnetic Fields

External magnetic influences can sometimes distort readings or cause false alarms. Proper shielding and placement help minimize this problem, but it’s a factor to consider when installing CBCTs in complex environments.

Limited Current Range

Some CBCTs are designed for lower currents and may not handle very high current conditions well. For large industrial systems, choosing a model with the right current capacity is vital to prevent overloads or inaccurate readings.

Common Troubleshooting Issues

Calibration can drift over time, reducing accuracy. Wiring errors or loose connections might also cause false readings or missed faults. Regular checks and adherence to manufacturer guidelines help keep CBCTs functioning accurately.

Installation and Use

Proper Placement and Mounting

Mount CBCTs where faults are most likely to occur, such as near ground points or equipment feeders. Follow manufacturer instructions to ensure correct orientation and secure fitting, optimizing detection sensitivity.

Calibration and Testing

Schedule routine calibration to confirm measurements stay accurate over time. Use testing devices to verify correct operation. Proper calibration prevents false alarms and ensures reliable safety alerts.

Integration with Protection Systems

CBCTs should connect seamlessly with relays, circuit breakers, or smart grid management tools. Compatibility guarantees faster responses to faults and more efficient energy management. Proper integration also helps in data collection for system analysis.