What is a Distribution Transformer?

Definition and Basic Functionality

At its core, a distribution transformer steps down high-voltage electricity into lower voltage levels that are usable for homes, businesses, and factories. Imagine it like a giant switch that reduces the power from the high-voltage lines you see on city streets to the voltage that outlets need. It fits within the larger power grid, connecting the high-voltage transmission lines to your neighborhood wiring.

Types of Distribution Transformers

There are two main types: wet-type and dry-type. Wet transformers use oil to cool and insulate, making them suitable for outdoor use. Dry transformers rely on air for cooling, often placed indoors where a fire risk is lower.

Another way to categorize is by phase. Single-phase transformers are common in small homes and businesses, providing power to individual buildings. Three-phase transformers serve larger systems, like shopping centers or industrial zones, delivering three power lines to handle more load efficiently.

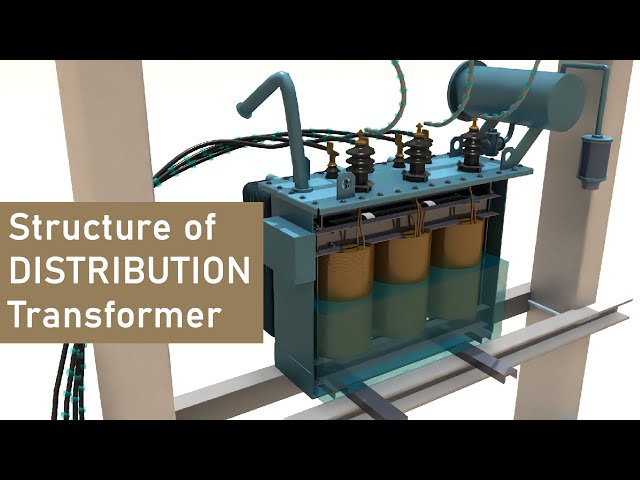

Components and Construction

A distribution transformer mainly comprises a core, windings, insulation, and protective covers. The core, usually made of silicon steel, channels magnetic flux. Copper or aluminum wires (windings) are wrapped around the core to transfer electrical energy. Insulation materials prevent short circuits, while protective features guard against environmental damage.

Features:

Voltage Ratings and Capacity

Most distribution transformers handle primary voltages ranging from 4kV to 35kV. The secondary side supplies about 120V or 240V, depending on location. Power ratings typically vary from a few hundred kVA (kilovolt-amps) to several MVA for large installations. Accurate sizing is key to prevent overloads and ensure safety.

Efficiency and Losses

Transformers are not 100% efficient. They lose some energy as heat. No-load losses happen even when no power is drawn, mainly due to core magnetization. Load losses increase as the transformer works harder. Higher efficiency reduces operational costs and lessens energy waste over its life.

Cooling Methods

Cooling helps keep transformers safe and operational. Oil-cooled types, marked as ONAN (Oil Natural Air Natural), circulate oil to transfer heat. Dry-type transformers use air cooling, often with fans or natural convection. Oil cooling can handle larger loads, but dry types are safer, especially indoors.

Maintenance, Testing, and Troubleshooting

Routine Maintenance Practices

Regular inspections keep transformers in top shape. Check for leaks, corrosion, or dirt build-up. For oil-filled models, periodic testing of oil quality and filtration prevents breakdowns. Keeping it clean and well-maintained extends the lifespan.

Common Issues and Their Remedies

Transformers can overheat, suffer insulation failure, or make unusual noises. Overheating might mean overload or poor cooling. Insulation issues can lead to short circuits, and strange sounds often point to core or winding problems. Routine diagnostics and timely repairs are essential.

Lifecycle and Replacement Planning

Transformers won’t last forever. Signs like increasing noise, decreasing efficiency, or visible damage suggest it’s time to replace. Planning ahead helps avoid unexpected outages. A cost-benefit analysis ensures you replace at the right time without overspending.

Concluding words:

Distribution transformers are vital for delivering electricity safely and efficiently. Picking the right type and maintaining it properly ensures a smooth power flow. Ongoing innovations promise even better performance, helping us build stronger, greener energy systems for the future.