What Is an Electric Arc?

Definition

An electric arc is a bright, glowing discharge that occurs between two electrodes when a high electric current passes through a gap. Think of it as a hot, glowing bridge formed by plasma, a super-hot, ionized gas. When two metal parts or electrodes come close, and enough voltage is applied, the electricity can jump across the space, creating an arc. This process involves gas breakdown and ionization, turning the air or other gases into a conductor that sustains the arc.

Types of Electric Arcs

- Stable vs. Unstable Arcs:

Stable arcs are continuous and predictable, perfect for welding. Unstable arcs may flicker or fluctuate, often unwanted, but sometimes useful in specific applications. - Indoor vs. Outdoor Arcs:

Indoor electric arcs are used in controlled environments like workshops, while outdoor ones are exposed to weather and pollution, affecting their behavior and safety measures.

Formation of an Electric Arc

The process begins when two electrodes come close and voltage is applied. First, a small stream of electrons jumps across the gap, ionizing the gas. Once enough ionization occurs, a conductive plasma forms, allowing a large current to flow and sustain the arc. The heat generated burns and melts metal, making electric arcs invaluable in welding.

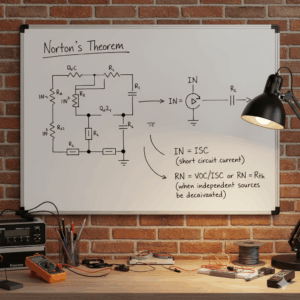

Physical and Electrical Properties

Electric arcs can reach temperatures of up to 10,000°C, hotter than the surface of the sun. This extreme heat makes them powerful tools for cutting and welding metals. Voltage drops within the arc range from a few volts to dozens, while the electrical current can vary from a few amperes to thousands, depending on the application.

Factors Influencing Arc Behavior

- Electrode Material and Shape:

Different metals produce different arc characteristics and weld qualities. The shape impacts how the arc strikes and maintains stability. - Gas Composition and Pressure:

The gases used around the electrodes (like argon or carbon dioxide) and their pressure affect arc temperature and stability. - External Magnetic and Electrical Fields:

Magnetic fields can bend or control the arc, useful in certain industrial processes.

Applications:

Welding and Metal Cutting

Electric arc welding is common everywhere—from building bridges to car repairs. Techniques like MIG, TIG, and stick welding use arcs to melt and fuse metals. These methods offer deep penetration, making strong welds. Electric arcs cut through metals quickly, enabling manufacturing and repair work to speed up significantly.

Lighting and Lena Products

Arc lamps and streetlights use electric arcs to produce bright, white illumination. They offer better efficiency and longer life compared to old-fashioned incandescent bulbs. Projectors and searchlights also rely on arc technology for powerful, focused beams.

Plasma Arc Technologies

In industry, plasma torches use electric arcs to reach extreme temperatures for cutting and welding thick metals. In healthcare, plasma technology is used in sterilization and medical treatments, thanks to its sterilizing power and precision.

Other Innovative Uses

Electric arcs are finding new roles in manufacturing automation, space propulsion, and even in experimental fusion reactors. Researchers hope future breakthroughs will turn electric arcs into sustainable energy sources.

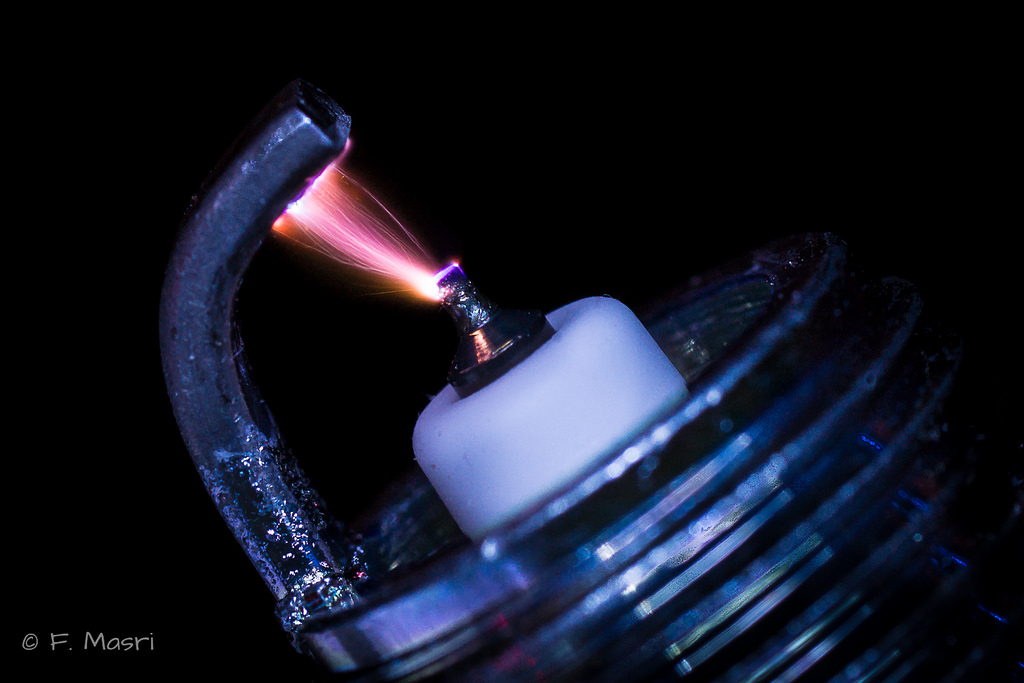

Spark Plugs:

who does not know about cars, trucks, vehicals today. In internal combustion engine spar plugs are main components for petrol engines. spark plugs work on electrical arc technology. when high voltage are applied across spark plugs, an arc is produced to burn fuel in engine.

Safety:

Risks Associated with Electric Arcs

Working with electric arcs involves risks like electric shock, severe burns, and fires. The intense heat can ignite nearby materials, and bright flashes can damage your eyes if proper eye protection isn’t used.

Protective Measures

Use gloves, face shields, and insulated clothing to keep safe. Set up safety barriers and warning signs around arc work sites. Proper training and emergency preparedness are crucial for everyone involved in arc-based work.

Environmental Impact and Mitigation

Electric arcs can produce ozone and nitrogen oxides, which harm the environment. They also consume significant energy. Improving efficiency, using cleaner gases, and filtering emissions can reduce their environmental footprint.

Conclusion

Electric arcs are powerful tools with a long history of transforming industry and technology. From welding to lighting and medical use, their many applications depend on understanding their principles. Safety remains a top priority, but ongoing innovations promise even more exciting uses in the future.

Professionals should always prioritize safety, keep up with new developments, and explore emerging arc applications for a more sustainable world. Electric arcs aren’t just sparks; they’re a key to shaping our technological future.