Principles of Fly back Transformers

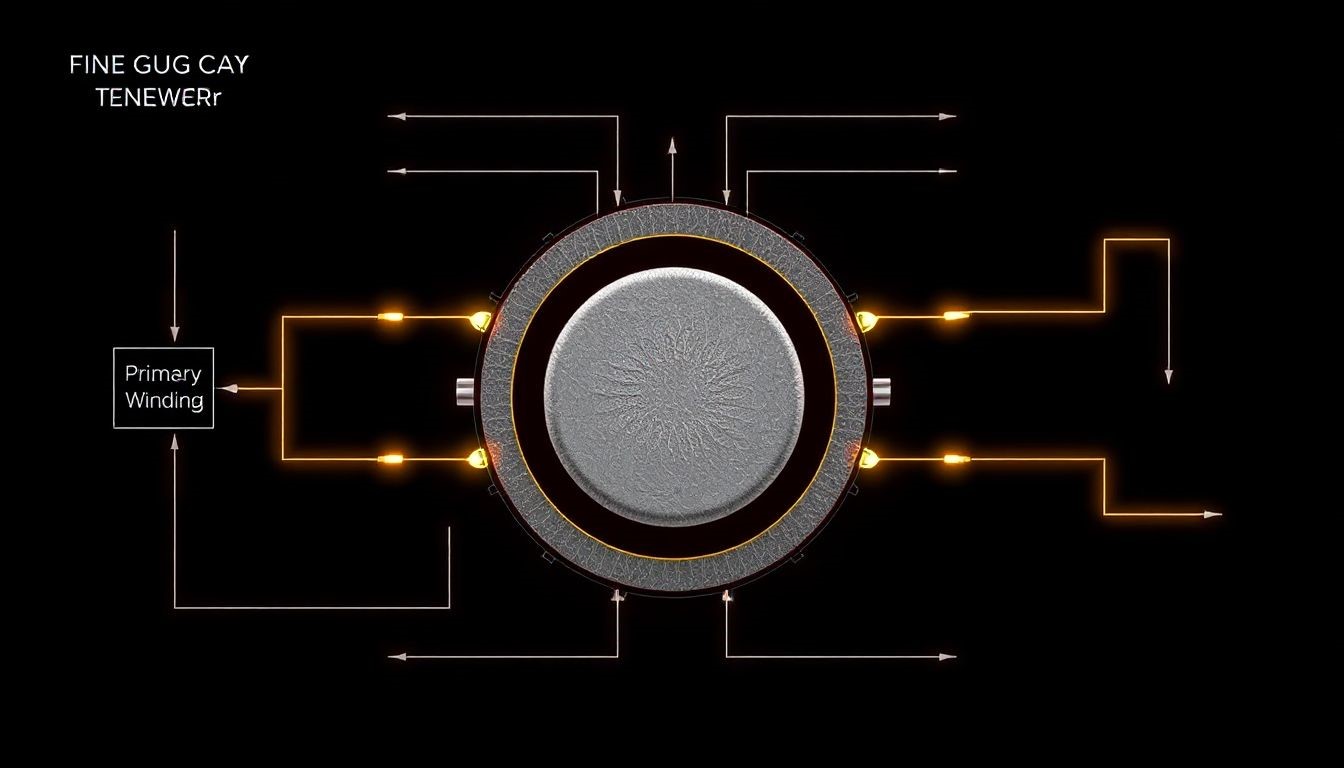

How a Fly back Transformer Works:

A fly back transformer operates on a unique principle of energy storage and release. Think of it like a temporary battery, but for magnetic energy. It doesn’t transfer power directly from input to output at the same time. Instead, it works in two distinct steps.

First, during the “on” phase, a switch connects the input voltage to the primary winding. Current flows through this winding, creating a strong magnetic field within the core. Energy gets stored in this magnetic field. The secondary winding remains off during this time.

Second, when the switch turns “off,” the primary current stops. The stored magnetic energy has nowhere to go but to collapse. This collapsing field induces a voltage in the secondary winding, pushing current out to the load. Energy then transfers from the core to the output circuit. This cycle repeats very quickly, making sure the output gets a steady flow of power. This is different from how a normal transformer passes power straight through.

Key Components and Their Roles

Every fly back transformer circuit relies on several key parts working together. Knowing what each does helps you grasp the whole picture.

The primary winding is where input energy first enters the transformer. It draws current from the power source when the switch is on. This action is crucial for building up the magnetic field inside the core. It’s the first step in the energy conversion process.

The secondary winding does the opposite. It receives the energy stored in the core and delivers it to the output. This winding also provides vital electrical isolation between the input and output sides. This means no direct electrical link exists, making devices safer.

The core material forms the heart of the transformer. Most often, designers pick ferrite for its magnetic properties. Ferrite cores are good at handling high frequencies and can store energy well. The choice of core directly impacts how much power the transformer can handle and how hot it gets.

A vital part of the core is the gap. This is a small, intentional break in the magnetic path. The gap is super important because it allows the core to store more energy. Without a gap, the core might get “saturated” too easily, which means it can’t store any more magnetic energy. This saturation can cause big problems and circuit failure.

Fly back Transformer vs. Other Transformer Topologies

Fly back transformers are just one type of switch-mode power supply design. Other common setups include forward, push-pull, and half-bridge topologies. Each has its own way of handling power.

A fly back converter stores energy in its magnetic core, then releases it. It typically uses just one main switching component. This makes it simpler and often cheaper for lower power uses, especially where isolation is needed.

In contrast, a forward converter transfers energy directly through the transformer when the switch is on. It does not store energy in the core like a flyback does. This design usually needs an extra winding or parts to reset the core after each cycle. Forward converters are often better for higher power levels.

Push-pull and half-bridge designs use two or more switching components. They transfer power continuously, not in separate storage and release phases. These designs are generally for higher power applications and can be more complex. However, they can be more efficient at high power outputs. Fly backs stand out for their simplicity and excellent isolation at lower power levels.

Applications of Fly back Transformers

Consumer Electronics: Powering Everyday Devices

Fly back transformers are everywhere in the consumer world. You likely use several every day without even knowing it. They are prized for their compact size and efficiency, making them perfect for devices you carry around.

Think about your phone or laptop charger. These small, lightweight adapters almost certainly use a fly back transformer. They convert the wall’s AC power into the steady DC power your devices need. This allows for safe, fast charging.

LED drivers in modern lighting and displays also rely on fly back technology. They precisely control the voltage and current to make LEDs shine brightly and last long. Many flat-screen TVs and audio equipment also use fly back converters in their internal power supplies. Their ability to step down voltage and provide isolation is key to these products.

Industrial and Medical Equipment

Beyond consumer gadgets, fly back transformers play a critical role in more demanding fields. In industrial and medical equipment, reliability and precision are not just nice to haves; they are necessities.

Industrial control systems, like those running factory machinery, need stable and isolated power. Fly back power supplies are often chosen for these jobs. They can handle a range of input voltages and deliver consistent output. This ensures machinery operates smoothly and safely.

Medical devices represent an even higher standard. Equipment such as patient monitors, diagnostic tools, and even some smaller surgical devices often use fly back transformers. They provide the crucial isolation needed to protect patients and medical staff from electrical hazards. Precise voltage outputs are also vital for accurate measurements and device function. Test and measurement equipment also benefits from their controlled power delivery.

Renewable Energy and EV Charging

The world is moving towards cleaner energy, and flyback transformers are part of this shift. They play a role in converting and managing power in renewable energy systems and electric vehicles.

In solar power, fly back transformers can be found in micro inverters. These devices attach to individual solar panels. They convert the DC power from the panel into usable AC power for your home. Fly backs are good for this because they are simple, compact, and offer isolation.

For electric vehicles (EVs), fly back converters are often used in onboard chargers. Especially for lower-power charging needs, they help convert the AC grid power into DC power for the car’s battery. Their efficiency and ability to handle varying voltage conditions make them a suitable choice for these vital applications.

Optimizing Fly back Transformer Circuits

Common Failure Modes and Diagnostics

Even well-designed fly back transformer circuits can run into problems. Knowing common failure modes helps you find and fix issues fast.

One frequent problem is overheating. This often points to high losses or poor thermal management. An output voltage that isn’t steady is another sign of trouble. This could mean issues with the control circuit or a faulty component. Sometimes, you might hear an audible noise or buzzing, which can signal problems like core saturation or loose windings. Of course, a complete component failure, like a shorted winding or a burnt switch, is also possible.

To find the fault, start with a visual inspection. Look for burnt components, bulging capacitors, or discolored circuit boards. Use a multi meter to take voltage and current measurements at different points in the circuit. This helps confirm if the power levels are correct. An insulation resistance test can check if windings are shorted or if isolation is compromised. Being systematic helps pinpoint the problem.

Improving Efficiency and Reducing Losses

Boosting a fly back converter’s efficiency means less wasted energy and cooler operation. There are several ways to improve performance.

One strategy is optimizing the duty cycle. This is the proportion of time the switch is “on” during each cycle. Adjusting it correctly ensures energy is transferred efficiently without overstressing components. Reducing leakage inductance is also key. Better winding techniques, like interleaving coils, minimize this wasted energy.

Minimizing parasitic capacitance can also help. This unwanted capacitance can cause oscillations and noise, reducing efficiency. Selecting lower-loss core materials is another direct way to cut down on energy waste. Newer materials are always being developed that offer better performance. A seasoned design engineer will tell you that paying close attention to component layout and selection can make a huge difference in overall efficiency. Every little bit counts.

EMI/EMC Considerations and Mitigation

Fly back circuits, with their fast switching, can generate electromagnetic interference, or EMI. This noise can mess with other electronics or even violate regulations. Dealing with EMI and ensuring electromagnetic compatibility (EMC) is a crucial design step.

The main sources of EMI in fly back circuits are the rapid switching of current and voltage, along with parasitic elements like unwanted capacitances and inductances. These fast changes create high-frequency noise that can radiate or conduct through wires.

Several techniques can mitigate EMI. Proper layout and grounding on the circuit board are fundamental. Keep traces short and direct to reduce antenna effects. Use a solid ground plane. Shielding, often with metal enclosures, can block radiated EMI from escaping the device. Snubber circuits, which are small RC or RCD networks, can absorb voltage spikes and reduce ringing, thereby cutting down noise. Lastly, input and output filtering, using capacitors and inductors, helps block EMI from entering or leaving the power supply lines.

Conclusion:

The fly back transformer truly stands as a cornerstone of modern power electronics. We’ve seen how its unique energy storage and release mechanism allows for efficient voltage conversion and critical isolation. From its core principles to the meticulous design considerations, every aspect plays a role in its widespread success.

Fly back transformers find homes across countless applications. They power the consumer electronics we use daily, ensure reliability in industrial and medical equipment, and even support the growth of renewable energy and electric vehicles. Their ability to provide stable, isolated power in a compact form makes them indispensable.