What is a Laser Diode?

Laser diodes make light using a clever trick of physics. It all starts with a semiconductor. This special material can conduct electricity better than an insulator but not as well as a metal. When you add energy, it can release light in a very controlled way. This process gives us the focused, strong light we know as a laser.

The Fundamental Principle of Laser Emission

Every laser diode works on a few simple ideas. These ideas involve how tiny particles behave in a special material. When electricity flows through this material, it sets off a chain reaction that creates light. This light is very different from a normal light bulb.

How a P-N Junction Creates Light

A laser diode contains a P-N junction. Think of it as two types of semiconductor materials placed together. One side, the P-type, has extra “holes” where electrons should be. The N-type side has extra electrons. When you send electricity through this junction, electrons from the N-side rush to fill holes in the P-side. This meeting is called electron-hole recombination. When an electron falls into a hole, it gives off energy. This energy comes out as a tiny packet of light, called a photon.

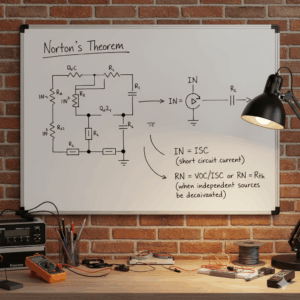

Stimulated Emission:

Most light sources create light randomly. This is called spontaneous emission. But a laser diode uses something better: stimulated emission. Imagine an electron about to give off a photon. If another photon, already in the material, hits this electron at just the right time, it makes the electron release its photon earlier. What’s more, the new photon is exactly like the first one. It has the same direction, color, and phase. This trick makes the light very orderly and powerful.

Optical Cavity and Amplification

To make the light strong and steady, a laser diode needs an optical cavity. This is like a tiny tunnel with mirrors at each end. These mirrors bounce the photons back and forth. As the photons travel, they hit more excited electrons, causing more stimulated emission. Each pass amplifies the light. This feedback loop creates a powerful, pure beam of light. It gives the laser its special qualities.

Components and Structure

A laser diode looks simple from the outside, but it has complex parts inside. Each part plays a key role in making and controlling the laser light. They all work together to produce a focused, strong beam.

The Semiconductor Material (Active Layer)

The most important part is the semiconductor material itself. This is where the light is actually made. Common materials include Gallium Arsenide (GaAs), Gallium Nitride (GaN), and Indium Phosphide (InP). The type of material decides the color, or wavelength, of the light. For example, GaAs makes red and infrared light. GaN helps make blue and green lasers. Different materials also affect how much power the laser can put out.

The Optical Cavity and Mirrors

The active layer sits inside the optical cavity. This cavity is often formed by cleaving the ends of the semiconductor crystal. These cleaved ends are then coated to be highly reflective, acting as tiny mirrors. Light bounces between these mirrors, passing through the active layer many times. This repeated bouncing and stimulating helps the light grow strong and aligned. The mirrors ensure the light travels in a straight line.

Electrical Contacts and Heat Sink

You need electricity to make a laser diode work. Electrical contacts bring current to the semiconductor material. As electricity flows, it makes heat. Too much heat can hurt the diode and shorten its life. That’s why a heat sink is crucial. This part pulls heat away from the diode, keeping it cool. A cool diode runs better and lasts longer.

Types of Laser Diodes:

Not all laser diodes are the same. Engineers design them in different ways for different jobs. These designs affect how the light comes out and what it can do. Knowing the types helps us understand their many uses.

Diode Laser Architectures

The way a laser diode is built changes its features. Some designs are great for sending data far away. Others are perfect for close-up tasks. Let’s look at a few main styles.

Edge-Emitting Lasers (EELs)

Edge-Emitting Lasers are perhaps the most common type. They shine light from the sides, or edges, of the semiconductor chip. This design creates a very focused, directional beam. They are often used in fiber optic cables for fast internet. EELs can make many different wavelengths and reach high power levels. They are known for their stable light output.

Vertical-Cavity Surface-Emitting Lasers (VCSELs)

VCSELs are special because they send light straight up from the surface of the chip. This is different from EELs. VCSELs are easier to make and can be grouped together in large arrays. They are good for short-distance tasks, like connecting parts within a computer or in smartphone sensors. These lasers are cheap to make and use less power.

Quantum Cascade Lasers (QCLs)

Quantum Cascade Lasers are quite unique. They do not work by electrons and holes meeting. Instead, QCLs use electrons moving between very thin layers of semiconductor material. This process lets them make light in the mid- and far-infrared range. These specific wavelengths are useful for finding gases or chemical sensing. They have very specialized applications where other lasers cannot reach.

Wavelength and Power Classifications

Laser diodes also differ in the color of light they make and how strong that light is. These factors greatly impact where and how we can use them. Different colors of light have different jobs.

Visible Spectrum Lasers (Red, Green, Blue)

These lasers make light you can see. Red laser diodes are in barcode scanners and many laser pointers. Blue and green laser diodes are used in display screens and Blu-ray players. The material Gallium Nitride (GaN) made blue and green lasers possible. This opened up new ways to store data and show images.

Infrared Lasers (Near-IR, Mid-IR, Far-IR)

Infrared (IR) light is invisible to the human eye. Near-IR lasers are common in telecommunications. They send data through fiber optic cables. Mid-IR and Far-IR lasers have uses in sensing and looking at chemicals. For example, they can detect certain gases in the air. These lasers are vital for many hidden technologies.

Power Levels: From Milliwatts to Kilowatts

Laser diodes come in a huge range of power outputs. Low-power ones, measured in milliwatts, are in consumer items like CD players. High-power laser diodes, reaching kilowatts, are for industrial jobs. They can cut and weld strong materials like steel. The power you need depends totally on the job you want the laser to do.

Applications of Laser Diodes

Laser diodes are quiet heroes. They power many big changes across different fields. Their small size and focused light make them perfect for jobs needing precision and speed. They have truly changed how we live and work.

Communication and Data Transfer

Imagine sending a text across the world in an instant. Laser diodes make this possible. They are the backbone of our fast, connected world. They move data with incredible speed and accuracy.

Fiber Optic Communication Networks

Laser diodes are essential for the internet and phone systems. They shoot tiny pulses of light down thin glass fibers. Each pulse can carry massive amounts of information. These fiber optic networks send your calls, videos, and website visits quickly across vast distances. Modern fiber lines can move more than a terabit of data each second. This allows for fast internet and clear communication globally.

Free-Space Optics (FSO)

Sometimes, laying cables is hard. Free-Space Optics uses laser beams to send data through the air. Think of it as a wireless fiber optic link. FSO works well for short to medium distances, connecting buildings or remote sites. It is fast and secure, needing a clear line of sight between the two points.

Industrial and Manufacturing Processes

In factories, laser diodes are powerful tools. They offer amazing precision. They can cut, weld, and mark materials with great accuracy. This makes manufacturing faster and more reliable.

Laser Cutting and Welding

High-power laser diodes can cut through thick metal sheets or weld parts together. They do this without touching the material. This method is very clean and precise. For example, in car making, lasers weld body panels together. This makes cars stronger and lighter. They also cut complex shapes for electronics.

Laser Marking and Engraving

Laser diodes can also leave a lasting mark. They burn or change the surface of a product. This is used for serial numbers, logos, or barcodes. It provides clear, lasting marks on almost any material. This helps track products and prevent fakes.

Medical and Healthcare Advancements

Laser diodes are changing medicine for the better. They offer gentle, precise ways to diagnose and treat health issues. Doctors use them for many kinds of treatments.

Surgical Procedures

Many surgeries now use laser diodes. In eye surgery, like LASIK, lasers reshape the eye to improve vision. In dermatology, they remove skin spots or unwanted hair. Lasers can cut tissue with very little bleeding. This means faster healing for patients. They give doctors incredible control during operations.

Diagnostic and Therapeutic Devices

Beyond surgery, laser diodes help in everyday health care. They are in devices like blood glucose meters. They also shine light through your finger in pulse oximeters to check oxygen levels. Some therapies use lasers to activate medicines in the body. For example, certain dental procedures use laser diodes for gum treatment.

Consumer Electronics and Everyday Technology

You probably use laser diodes every day without knowing it. They are tucked away inside many common devices. They make our daily tasks easier and more efficient.

Barcode Scanners and Optical Drives

When you buy groceries, a red laser diode in the scanner reads the barcode. This quickly tells the price. In your computer, optical drives for CDs, DVDs, and Blu-ray discs use laser diodes. They read and write data to these discs with tiny, focused beams.

Laser Printers and Projectors

Laser diodes are key to creating crisp, clear documents. In laser printers, a diode draws the image onto a drum. This image then transfers to paper. In small projectors, laser diodes make bright, sharp pictures on a screen or wall. Some 3D printers use laser diodes for curing resins or sintering powders.

Factors Affecting Laser Diode Performance

Choosing the right laser diode means looking at many features. How it works, how long it lasts, and its light quality are all important. These factors decide if a diode is right for a certain job.

Wavelength Stability and Spectral Purity

For many jobs, the color of the light must stay the same. It also needs to be very pure. This means the laser only produces one very specific color. Any changes can mess up the results.

Temperature Effects on Wavelength

The temperature around a laser diode can shift its emitted wavelength. If it gets hotter, the color might change slightly. This is bad for tasks needing exact colors, like some sensors. To stop this, designers often add cooling systems. Keeping the diode cool helps it keep a steady color.

Spectral Linewidth and Coherence Length

Spectral linewidth refers to how narrow the laser’s color band is. A smaller linewidth means a purer color. Coherence length tells you how far the light waves stay in sync. For precise tasks, like measuring tiny distances or scientific tools, you need a very pure and coherent laser. These features are key in high-tech fields.

Power Output and Efficiency

How strong a laser diode is and how well it turns electricity into light matter a lot. These things affect how much energy it uses and how much heat it makes. Finding the right balance is important.

Electrical-to-Optical Conversion Efficiency

This number shows how much electrical power becomes light. A high efficiency means less wasted energy as heat. This helps with battery life in portable devices. It also means less money spent on cooling big industrial lasers. Picking an efficient diode saves energy and cuts costs.

Beam Quality and Divergence

Beam quality describes how well the laser light can be focused. Divergence is how much the beam spreads out over distance. A low divergence means the beam stays tight. These factors are critical for focusing light into a fiber or cutting very small parts. A good beam quality helps with precision.

Actionable Tip: When selecting a laser diode, prioritize efficiency for battery-powered devices or lower thermal management costs.

Reliability and Lifespan

You want your laser diode to work for a long time without breaking. How long it lasts depends on its design and how you use it. Knowing its limits helps it last longer.

Degradation Mechanisms

Laser diodes can fail for various reasons. Tiny flaws in the material can grow over time. The mirrors can get damaged. Too much heat or current can also wear them out faster. These issues slowly degrade the laser’s performance.

Operating Conditions and Lifetime Estimates

How you use a laser diode greatly impacts its life. Running it at very high power or temperature will shorten its life. Using it within its safe limits, however, helps it last for many years. Manufacturers give a Mean Time Between Failures (MTBF) number. This tells you how long a high-quality laser diode should last on average. Many industrial laser diodes boast over 100,000 hours of operation before major failure.

Summary

Laser diodes stand as a core part of modern technology. They offer a small, powerful, and versatile light source. They profoundly impact everything from global networks to life-saving medical care. Their reach is vast. As research improves materials and design, we can expect even more amazing uses for these semiconductor devices.

The journey from basic physics to complex laser systems shows human cleverness. Whether powering your internet connection, enabling precise factory work, or helping with medical procedures, laser diodes are essential. Understanding how they work, their types, and their growing abilities is key. It helps us see the tech around us and what is coming next.