What is a Magnetic Core?

A magnetic core is a special material that helps focus and strengthen magnetic fields. Think of it like a highway for magnetic flux. It guides the magnetic energy, making it much stronger and more useful. Without these cores, many devices would not work well, or even at all.

Definition and Fundamental Principles

We use a magnetic core to concentrate magnetic flux. This makes transformers and inductors much more efficient. It is a vital part for controlling electric currents and magnetic fields.

Magnetic Materials

Some materials are better than others at handling magnetic fields. Ferromagnetic materials, like iron, are strongly attracted to magnets. They hold onto magnetism well. Ferromagnetic materials, like ferrites, are also magnetic but have higher electrical resistance. This makes them great for high-frequency uses. Paramagnetic materials are only weakly magnetic. They aren’t usually used for cores. We choose specific materials for magnetic cores based on their magnetic properties and how they perform at different frequencies.

Magnetic Flux and Permeability

Magnetic cores greatly boost magnetic flux density. This means more magnetic field lines can pass through a smaller area. This happens because of a property called permeability. Permeability tells us how easily a material lets a magnetic field pass through it. A high-permeability core means the magnetic field can be much stronger.

The Science Behind Magnetic Cores

The way magnetic cores work depends on some cool physics. Getting a grip on these ideas helps us see why core choice matters so much. They make sure power moves smoothly in many different circuits.

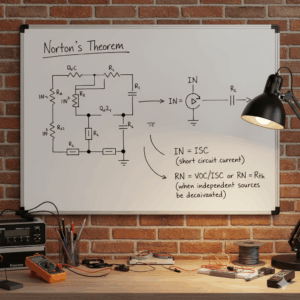

Hysteresis and Core Losses

When an alternating current (AC) flows, the magnetic field in a core constantly reverses direction. This reversal takes energy, and some of it is lost as heat. This energy loss is called hysteresis loss. Another problem is eddy currents. These are small electric currents that swirl within the core itself. They also cause energy loss and heat, reducing efficiency.

Saturation

Every magnetic core has a limit to how much magnetic flux it can handle. When you push too much magnetic field through a core, it reaches saturation. At this point, the core cannot concentrate any more magnetic flux. If a core saturates, the device can stop working correctly. It can cause distortion or even damage components.

Types of Magnetic Cores

Magnetic cores come in many shapes and are made from different stuff. Each type has its own strengths for certain jobs. Knowing these differences helps engineers pick the best core for a specific task.

Common Core Shapes

Core shapes are picked based on where they’ll be used. Their design impacts how well they perform. This includes how much energy they lose and how well they shield against outside interference.

Toroidal Cores

Toroidal cores look like a donut. They are very efficient because their round shape minimizes magnetic flux leakage. This makes them great for high-performance transformers and inductors. Their design helps keep the magnetic field mostly inside the core.

E-I Cores

E-I cores are common and look like the letters “E” and “I.” They are cost-effective and easy to make. You’ll often find them in power transformers for household electronics. Their simple shape allows for easy winding of wires.

Pot Cores and RM Cores

Pot cores and RM cores fully enclose the winding. This helps shield against electromagnetic interference (EMI). They are good for high-frequency tasks where noise must be kept low. These shapes also offer good mechanical protection for the windings.

Other Shapes (e.g., U-cores, Rod Cores)

Other shapes exist for special uses. U-cores pair with I-cores to form a rectangular loop, similar to E-I cores. Rod cores are simple cylinders. They are often used for small inductors or antennas in niche applications. Each shape serves a distinct purpose in electronics.

Key Core Materials

The material a core is made from truly changes how it works. Different materials offer unique properties. Engineers select them for specific needs, such as frequency range or power handling.

Ferrites

Ferrites are ceramic magnetic materials. They have very high electrical resistivity. This means they have low eddy current losses, especially at high frequencies. That’s why ferrites are perfect for high-frequency transformers and EMI filters. They keep things cool and efficient.

Powdered Iron

Powdered iron cores are made by compressing small iron particles with a binder. They are cost-effective and can handle higher DC currents without saturating. This makes them ideal for inductors in power supplies. They manage magnetic fields well under heavy loads.

Amorphous and Nanocrystalline Alloys

Amorphous and nanocrystalline alloys are newer materials. They offer superior magnetic properties like very low losses and high permeability. These are used in advanced power supplies and high-efficiency transformers. They boost performance in demanding applications.

Silicon Steel (Laminations)

Silicon steel is a standard for power frequency transformers, like those in our power grid. It has good magnetic properties and is affordable. We often use it in thin sheets, called laminations, to reduce eddy current losses. This helps power flow smoothly across long distances.

Applications of Magnetic Cores

Magnetic cores are quietly doing big work in so many places. From charging your phone to powering city lights, they are everywhere. Let’s look at some key areas where they shine.

Power Electronics and Energy Conversion

Magnetic cores are the unsung heroes of power management. They help convert and manage electricity efficiently. Without them, our power systems would be much less effective.

Transformers

Transformers use magnetic cores to change AC voltages. They can step up voltage for long-distance transmission or step it down for household use. This is crucial for our power grids and for powering all your electronic gadgets safely.

Inductors

Inductors store energy in a magnetic field. Magnetic cores are key to their function in switched-mode power supplies (SMPS). Inductors also filter out noise, helping to smooth electrical currents. They ensure a steady power supply for sensitive circuits.

Current Transformers (CTs)

Current transformers (CTs) use cores to measure large AC currents safely. They scale down the current to a measurable level. This protects equipment and helps monitor power use in industrial settings. They are vital for electrical safety and data.

Signal Processing and Telecommunications

Magnetic cores don’t just handle power; they also process information. They help send and receive signals cleanly. This makes our communication systems clear and reliable.

EMI/RFI Filtering

EMI (Electromagnetic Interference) and RFI (Radio Frequency Interference) filtering is where cores really help. We use cores in chokes and beads to suppress unwanted electrical noise. This ensures our devices don’t interfere with each other. It also keeps your radio signal clear.

High-Frequency Inductors and Transformers

For things like radio frequency (RF) circuits and wireless communication, high-frequency inductors and transformers are a must. Magnetic cores make these components work well at rapid speeds. They are vital for sending data quickly and clearly.

Emerging and Specialized Applications

Magnetic cores are even used in some surprising and high-tech ways. Their ability to manage magnetic fields opens up new doors. They continue to enable innovation in many fields.

Magnetic Resonance Imaging (MRI)

In medical fields, Magnetic Resonance Imaging (MRI) machines use powerful magnetic fields. While the main field is often created by superconducting magnets, some parts use magnetic cores. They help shape and control the smaller magnetic fields needed to get clear body images.

Data Storage (Historical and Niche)

Decades ago, magnetic core memory was a major way to store computer data. Each core held one bit of information. Today, while largely replaced by other tech, magnetic principles still apply in some niche data storage. They show the enduring power of magnetism.

Magnetic Sensors

Magnetic sensors use cores to detect changes in magnetic fields. These sensors are in many devices, from proximity sensors in your phone to industrial position detectors. They can tell if something is near or how fast something is spinning.

Factors Influencing Magnetic Core Selection

Choosing the right magnetic core isn’t simple. Several key factors guide the decision. Picking the best core means your device will work well and last longer.

Performance Parameters

The core’s performance is tied to its inherent properties. These parameters tell us how efficient and stable the core will be. They are crucial for good circuit design.

Permeability and Flux Density

Permeability tells us how easily a core material allows a magnetic field to form within it. A high-permeability core can create a strong magnetic field with less effort. Flux density is the amount of magnetic field passing through an area. These two traits directly affect how powerful your transformer or inductor will be.

Core Losses (Power Dissipation)

When a core loses energy, it turns into heat. This is known as core losses or power dissipation. High core losses mean less efficiency and more heat. Engineers must balance power loss against other design needs. Reducing these losses is key for cool-running, efficient devices.

Saturation Flux Density

The saturation flux density is the maximum magnetic field a core can handle before it stops working properly. Going past this point causes problems like signal distortion or device failure. Knowing this limit is vital to prevent circuits from malfunctioning.

Environmental and Operational Considerations

Beyond basic performance, how and where a core will operate matters a lot. External conditions can affect how well a core works. Designers must keep these in mind for a reliable product.

Temperature Range

A core’s properties can change with temperature. Some materials lose efficiency or become unstable when too hot or too cold. Designers must choose cores that perform well across the expected temperature range of the device. This ensures consistent operation.

Frequency of Operation

The frequency of operation is a huge factor. At higher frequencies, certain cores develop much higher losses. Ferrite cores, for example, shine at high frequencies, while silicon steel is better for lower, power-line frequencies. Matching the core material to the operating frequency is critical.

DC Bias Current

Sometimes, a DC (direct current) flows through the windings of a core along with the AC signal. This DC bias current can push the core closer to saturation. It reduces the core’s effective permeability. Engineers must pick cores that can handle the DC bias without losing too much performance.

Conclusion

Magnetic cores truly are the “invisible” workhorses of modern electronics. They ensure power flows smoothly and signals get processed cleanly. From the power grid to your smallest gadget, their role is essential.

Picking the right magnetic core involves understanding materials, shapes, and their specific jobs. Engineers must consider factors like permeability, losses, and operating conditions. These choices decide how well a device will perform.

As technology keeps advancing, so will magnetic core design and materials. We can expect even more efficient, smaller, and powerful solutions in the future. Magnetic cores will remain at the heart of innovation.