Principles of Electrical Machines

The Electromechanical Conversion Process

Electrical machines work by turning one type of energy into another. They shift between electrical energy and mechanical energy. This amazing process makes them work. It’s all based on how electricity and magnetism interact.

Electromagnetic Induction: The Heart of Operation

A key idea here is Faraday’s Law of Induction. It says that a changing magnetic field creates an electric current. Think of it like this: if a magnet moves near a wire, it makes electricity flow. Lenz’s Law explains the direction of this current. It always opposes the change that caused it. This push and pull is how machines start.

Magnetic Fields and Their Role

Electric currents make magnetic fields. This is Ampere’s Law in action. You see this when electricity flows through a wire coil. The strength of this field depends on the current. Machine parts often use materials like iron. These materials make magnetic fields stronger and guide them better.

Types of Electrical Machines

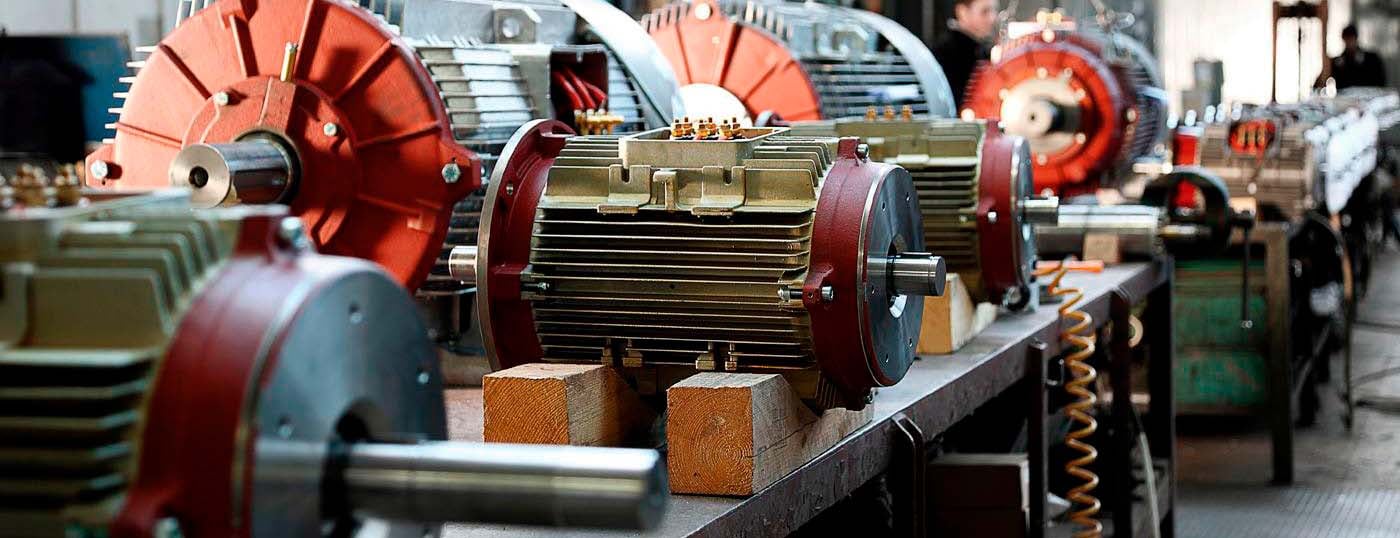

Rotating Electrical Machines: Motors and Generators

Most electrical machines move or spin. These are called rotating machines. They either make motion from electricity or electricity from motion. Motors and generators are the two main kinds. They do opposite but related jobs.

Electric Motors: Converting Electricity to Motion

Electric motors take electricity and turn it into movement. They are found in many places. DC motors, like those in toys or electric vehicles, use direct current. AC motors, used in fans or large factory equipment, use alternating current. Some AC motors, called induction motors, are common in industry. Others, synchronous motors, keep a steady speed.

Electric Generators: Producing Electricity from Motion

Generators do the reverse of motors. They take motion and create electricity. Imagine a spinning turbine in a power plant. This motion makes electricity. Synchronous generators are found in big power stations. Asynchronous generators are often used with wind turbines. They help bring renewable energy into our homes.

Static Electrical Machines: Transformers

Some electrical machines do not move at all. These are called static machines. Transformers are a perfect example. They manage electricity without any spinning parts. They are vital for how we get power.

The Principle of Electromagnetic Transformation

Transformers work using mutual induction. This means one coil’s magnetic field affects another coil nearby. They change voltage levels up or down. This lets power move over long distances efficiently. An “ideal” transformer would lose no energy at all.

Applications and Significance of Transformers

Transformers are critical for power lines. They step up voltage for long-distance travel. Then they step it down for safe use in homes. This process greatly reduces energy loss. Without them, about 80% of generated power would be lost. They are also in small electronic items. Think of your phone charger; it uses a tiny transformer.

Key Components

The Stator and Rotor: The Moving and Stationary Parts

Every rotating electrical machine has two main parts. One stays still, the other spins. These parts work together to convert energy. Their design is key to how well the machine works.

Stator Design and Construction

The stator is the stationary part of the machine. It often holds the main windings. These windings create a steady or rotating magnetic field. Stators are usually made from laminated steel sheets. This design helps reduce energy loss from eddy currents.

Rotor Design and Functionality

The rotor is the spinning part. It interacts with the stator’s magnetic field. This interaction causes the rotor to turn. In induction motors, you might see a “squirrel cage” rotor. Other motors use wound rotors or permanent magnets. Each type matches a specific machine.

Windings, Commutators, and Brushes

Beyond the main frame, other parts are crucial. These help electricity flow and direct magnetic fields. They ensure the machine works right. These small pieces have big jobs.

The Role of Windings in Magnetic Field Generation

Windings are coils of insulated copper wire. Electricity flows through them. This flow creates the magnetic fields needed for operation. How they are arranged matters a lot. It decides the machine’s power and speed.

Commutators and Brushes in DC Machines

DC motors have special parts called commutators and brushes. The commutator reverses the direction of current in the rotor coils. This keeps the rotor spinning in one direction. Carbon brushes press against the commutator. They transfer electricity to the spinning parts. Brushes wear down over time and need replacing.

Future Prospects

Innovations in Design and Control

Electrical machines are always getting better. New materials and smart systems are changing them. These changes make machines stronger and smarter. They can do more with less power.

Advances in Materials Science

New magnetic materials are making motors smaller and more powerful. Superconductors could one day carry electricity with no loss. Better insulation means machines can handle higher temperatures. These material improvements boost efficiency greatly. They also allow for more power in a smaller space.

Smart Control Systems and IoT Integration

Modern machines use advanced control systems. Variable Frequency Drives (VFDs) change motor speed precisely. The Internet of Things (IoT) lets machines talk to each other. Sensors can monitor performance in real-time. This helps predict when maintenance is needed. Machines can even adjust themselves for best performance.

Electrification Trends and Sustainability

Electrical machines are key to a greener future. They are at the heart of new energy solutions. From how we drive to how we power our homes, they are changing everything. This shift helps the planet.

The Role of Electrical Machines in Electromobility

Electric vehicles are growing fast. Electrical machines, like traction motors, make them move. These motors are powerful and efficient. They are also quieter and cleaner than gas engines. This trend greatly reduces pollution from cars.

Energy Efficiency and Renewable Energy Integration

Better electrical machines mean less wasted energy. This helps businesses save money. They also make it easier to use renewable energy. Wind turbines and hydro dams rely on generators. Advances in these machines help us use more clean power. This builds a more sustainable world for everyone.

Conclusion

Electrical machines are truly fundamental to our modern lives. They are an unseen, yet vital, force. From small gadgets to huge power plants, they make our world work. Their varied types and simple principles show their amazing flexibility. As we look ahead, ongoing innovation will make these machines even better. They are crucial for a sustainable and efficient future