What Is a Voltage to Current Converter?

Definition and Functionality

A voltage to current converter turns an input voltage into a corresponding current output. It makes sure that the amount of current matches the voltage applied. Unlike simple voltage dividers, these converters give a steady current that accurately reflects the input voltage. This means the signal stays reliable even if conditions change.

Key Advantages

- Better signal quality over long wires: Current signals don’t weaken as much over distances, unlike voltage signals.

- Less noise interference: They resist interference from electrical noise, keeping signals clean.

- Compatibility with industry standards: Many systems use current signals like 4-20mA, making these converters ideal for automation.

Principles of Voltage to Current Conversion

Basic Working Principle

The core idea is simple: the converter takes a voltage input and makes a proportional current output. Imagine turning a volume knob; higher voltage equals higher current. This happens through carefully designed circuits that keep the relationship consistent across different levels.

Ohm’s Law and Its Role

Ohm’s Law (V=IR) is the foundation. In a voltage to current converter, the circuit uses a resistor to control current. If the input voltage increases, the current according to Ohm’s Law also rises, keeping the output proportional.

Linearity and Accuracy Considerations

To trust these converters, they must be linear—meaning the output current increases steadily with voltage. Any distortion could cause incorrect readings. Proper design, component choice, and calibration help keep the conversion accurate.

Types of Voltage to Current Converters

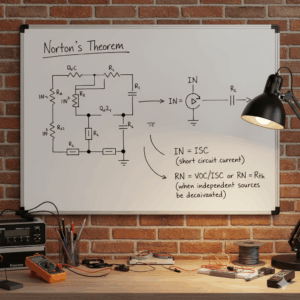

Trans conductance Amplifier-Based Converters

Trans conductance amplifiers change voltage into current directly. These are suited for high-precision applications like scientific measurements. They are reliable but can be more complex to set up.

Active and Passive Circuit Designs

- Active circuits: Use operational amplifiers, transistors, or integrated chips. They offer high accuracy and flexibility but need power.

- Passive circuits: Rely on resistors and transistors without amplifiers. They are simpler and cheaper but may have lower precision.

Current Source vs. Voltage Source Converters

- Current source designs: Best when load conditions change or when long-distance signal transmission is needed.

- Voltage source designs: Work well with fixed loads and simpler systems. They are easier to build but less flexible.

Design and Implementation

Selecting Components

Pick components based on:

- Signal bandwidth: How fast the voltage changes.

- Impedance: To match with sensors or loads.

- Linearity: For precise measurements. For example, precision op-amps or low-noise transistors are common choices.

Circuit Topologies

Some typical setups include:

- Op-amp based circuits: Use feedback to improve stability.

- Transistor circuits: Offer simple designs for basic applications. To get good results, keep layouts tight and avoid unnecessary wiring.

Calibration and Testing

Calibrate your system with standard signals to check accuracy. Use multi meters and current meters for testing. Make adjustments to ensure the output matches expected values consistently.

Real-World Examples of Voltage to Current Converters

Industrial Sensors

Many industrial sensors operate in 4-20mA current loops. These signals are immune to electrical noise, making them perfect for factory environments. They can transmit data across long cables without losing quality.

Instrumentation Applications

Precision measurement tools rely on voltage to current converters. They help ensure readings are accurate, especially in labs or calibration stations.

Automation and Control Systems

PLCs and other automation controllers often use current signals to control machinery. The converters help translate sensor signals into usable data for automated decisions.

Concluding words:

Voltage to current converters are key in many industrial and measurement systems. Choosing the right type and proper design can make a big difference in performance. Focus on calibration, quality components, and noise control for best results. As technology advances, these circuits will become even more important in smarter, more connected systems.